General introduction

The primary purpose of a penstock is controlling the flow of water to prevent changes in water level. The flow of the water through the penstock can be controlled with a sluice gate that is raised and lowered. When the sluice is fully open, water flows freely through the penstock. When it is closed, the water is limited and less water enters.

Description

- Suitable for any application

- Multiple Material and Size Options

- Excellent watertightness, leakage rate below 0.1 l/sec/meter of seal

- Simple and easy to operate

- Customize for control panel options

- Sturdy design, low-maintenance process

Application

- Water treatment plants

- Wastewater treatment plants

- Desalination plants

- Hydroelectric power plants

- Irrigation installations

- Sewers, Storm Tanks, Drain Manifolds

Penstock Types

| Type | Chanel Penstock | Wall Penstock | Weir Penstock | Tilting gate |

| Product Guiding | Shaped welding frame, installation on concrette wall at the end of pipehole. Seal shape V type and L type with higher performance. The most popular type application. | Shaped welding frame, installation inside middle of concrette chanel to prevent the flow. Seal shape V type and L type with higher performance. | Shaped welding frame, installation on concrette wall at the end of pipehole. Seal shape V type and L type with higher performance. Use to outlet or adjust the water level | Welded frame with lateral sealing. Installation on discharge channel to control or adjust the level |

| Seal | 4 Side Seals Type shape: V, P, L | 3 Side Seals Type shape: V, P, L | 3 Side Seals Type shape: V, P, L | 3 Side Seals Type shape: V, P, L |

| Operation | Manual Automatic | Manual Automatic | Manual Automatic | Manual Automatic |

| Application | Install on the outlet pipe or chanel, for controlling On/ Off the Flow | Install in the midle chanel, for controlling On/ Off the Flow | Install in the midle chanel, for controlling On/ Off the Flow | Install on the discharge chanel, for controlling On/ Off the Flow, prevent back flow |

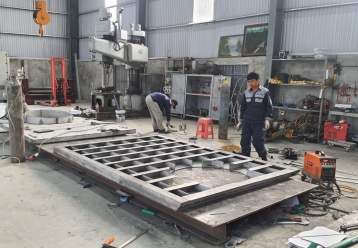

Penstock Component

| No. | Penstock Component | Materials available |

| 1 | Frame | Carbon steel or stainless steel grade, AISI/SUS304, AISI/SUS304L, AISI/SUS316, AISI/SUS316L, AISI/SUS316Ti |

| 2 | Door / Slide | Carbon steel or stainless steel grade, AISI/SUS304, AISI/SUS304L, AISI/SUS316, AISI/SUS316L, AISI/SUS316Ti |

| 3 | Operating Stem / Spindle | Carbon steel or stainless steel grade AISI/SUS304, AISI/SUS304L, AISI/SUS316, |

| 4 | Drive mechanism | Manual, Reducer, Electric Actuator |

| 5 | Spindle protection tube (for rising spindle) | Polycarbonate , Hot dip galvanize ,AISI/SUS304, AISI/SUS316L |

| 6 | Console /Headstock | Aluminum, Carbon steel or stainless steel grade AISI/SUS304, AISI/SUS304L, AISI/SUS316, AISI/SUS316L, AISI/SUS316Ti, DUPLEX or SUPER DUBLEX |

| 7 | Seal | Neoprene / EPDM |

| 8 | Wedge | POM |

| 9 | Assembly Fasteners | A2 , A4 |

| 10 | Fixing Bolts | A2 , A4 |

This model including penstocks 4 side seals, with dimension of Width x Height of discharge/ hole/ chanel around 1000 - 1800mm. We called that Medium Size. With special dimension, pls Contact us for more support.

Sizes from DN 150 to approx. DN 1000, even in rectangular or square shape. The material range includes hot dipped galvanized steel, aluminium alloy, HDPE, stainless steel 304 (1.4301), 316 (1.4571)

- Flow Control

- Water Treatment

- Wastewater Treatment